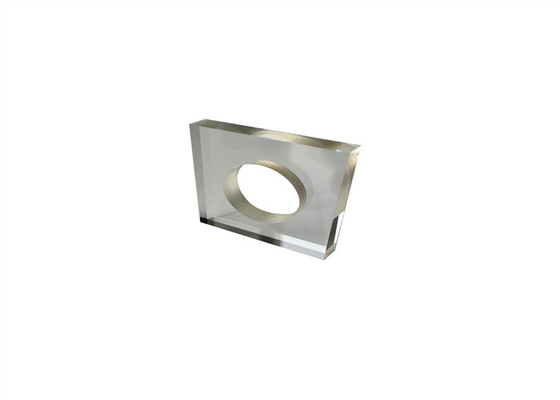

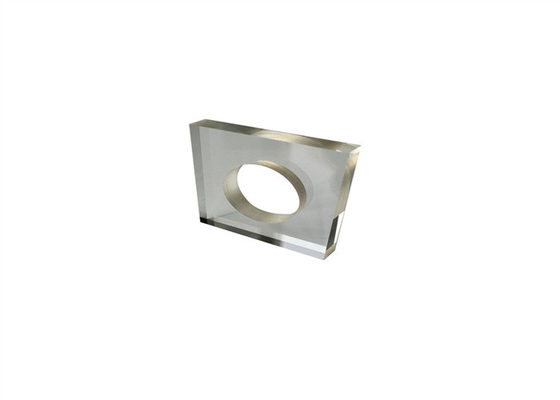

Drilled hole optical glass window with all faces polished

| Bevel | 0.5mm X 45° | Surface Quality | 60/40 |

|---|---|---|---|

| Size | 24x24mm | Flatness | <λ/4@632.8nm |

| Polish | All Surfaces Polished | Color | Clear, Transparent, Etc. |

| Shape | Square With Drilling Hole At Center | Parallelism | <3 Arc Minutes |

| Highlight | Drilled Hole Glass Window,Drilled Hole Optical Glass Window |

||

Product Description:

A drilled hole optical glass window with all faces polished is a specialized type of glass window that has a hole drilled through it and all of its faces carefully polished to achieve high optical clarity and smoothness. This type of window is commonly used in various optical and imaging applications where precise light transmission and minimal distortion are required.

Key Features:

Here are some key features and considerations of a drilled hole optical glass window with all faces polished:

- Optical Clarity: The glass used in these windows is selected for its excellent optical properties, such as low absorption and high transparency. This allows for minimal light loss and distortion when the window is used in optical systems.

- Drilled Hole: The window has a precisely drilled hole passing through it. The size and shape of the hole can vary depending on the specific application requirements. The drilling process must be carefully controlled to ensure a clean and accurate hole without damaging the surrounding glass.

- Polished Faces: All faces of the window, including the external surfaces and the inner walls of the drilled hole, are polished to a high degree of smoothness. This polishing process removes any surface imperfections, scratches, or roughness, which could otherwise cause light scattering or distortion.

- Surface Flatness: The polished faces of the window are made flat to maintain the integrity of the optical system. Flatness is essential to ensure that light passing through the window remains undistorted. The degree of flatness required depends on the specific application and the level of precision needed.

- Coatings: In some cases, optical coatings may be applied to the polished surfaces of the window to enhance its performance. These coatings can reduce reflections, increase light transmission, or provide specific wavelength properties to meet the requirements of the optical system.

- Material Selection: The choice of glass material for the window depends on the specific application. Different types of optical glass, such as borosilicate, fused silica, or quartz, may be used based on factors like refractive index, thermal stability, and chemical resistance.

Technical Parameters:

| Features | Description |

|---|---|

| Parallelism | <3 Arc Minutes |

| Size | 24x24mm |

| Polish | All Surfaces Polished |

| Material | high borosilicate glass |

| Bevel | 0.5mm X 45° |

| Color | Clear, Transparent, Etc. |

| Surface Quality | 60/40 |

| Flatness | <λ/4@632.8nm |

| Shape | Square With Drilling Hole At Center |

| Usage | Used to bond vacuum chambers |

Applications:

Applications of drilled hole optical glass windows with polished faces include:

- Optical systems: These windows are commonly used in optical instruments, cameras, microscopes, telescopes, and laser systems to allow light to pass through while maintaining optical quality.

- Imaging devices: They can be employed in cameras, sensors, and imaging systems that require precise light transmission and minimal distortion.

- Industrial and scientific applications: Drilled hole optical glass windows find utility in various industrial and scientific equipment, such as spectrometers, analytical instruments, and inspection systems.